Factory

Located in the municipality of Fano, on the Adriatic coast of central Italy, our plant has been evolving for 35 years. Our local climate and proximity to logistical hubs has always contributed to the extreme speed with which we manufacture and supply PCBs to all our customers, because our lead times for production and shipment are intrinsically short.

Our PCB production facility is laid out on a single floor, with an indoor area of 1700 square metres, to facilitate production flows and minimise semi-finished PCB handling operations. It also has an outdoor area of 800 square metres for the handling of pallets, bins and pallet tanks, and the reception of express couriers.

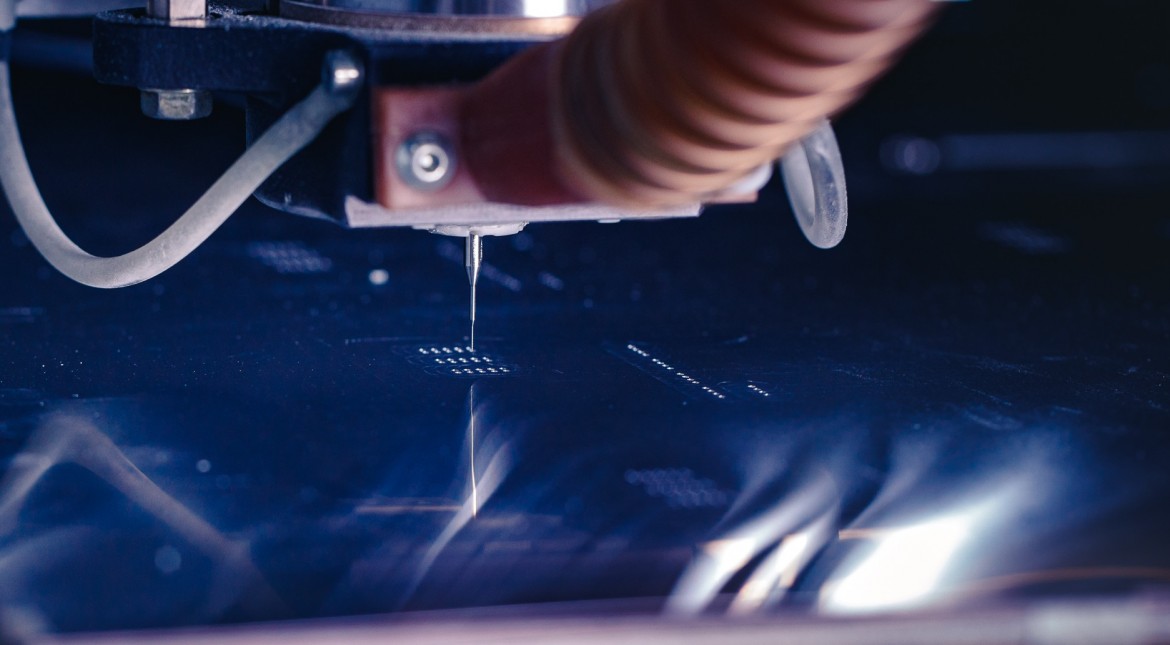

Production operations are organised into the following departments: cleanroom, where the PCBs are exposed to ultraviolet radiation; chemical warehouse and chemical lines, laminate warehouse and CNC machining, metallographic laboratory and press for multi-layer and rigid-flex PCBs, technical department, including master designer and machine programmer, and ATE flying probe electrical testing. This configuration facilitates the development and cross-departmental transfer of know-how, and enables us to manufacture PCBs according to both push and pull logistical models, thus ensuring accurate Material Requirements Planning (MRP) to the benefit of the entire supply chain.

The management, sales and marketing departments are all located in the same building, and interface with customers on technical, financial and promotional matters. In exceptional cases, moreover, the resulting structure enables PCB circuit diagram and wire routing designers, and assemblers of both PTH and SMD circuit boards, to liaise directly with our technical department master designer and the production manager in order to resolve any technical problems through a collaborative approach that generates unambiguous answers, all under the constant supervision of the finance and sales function.