Markets

The PCB market is highly diversified.

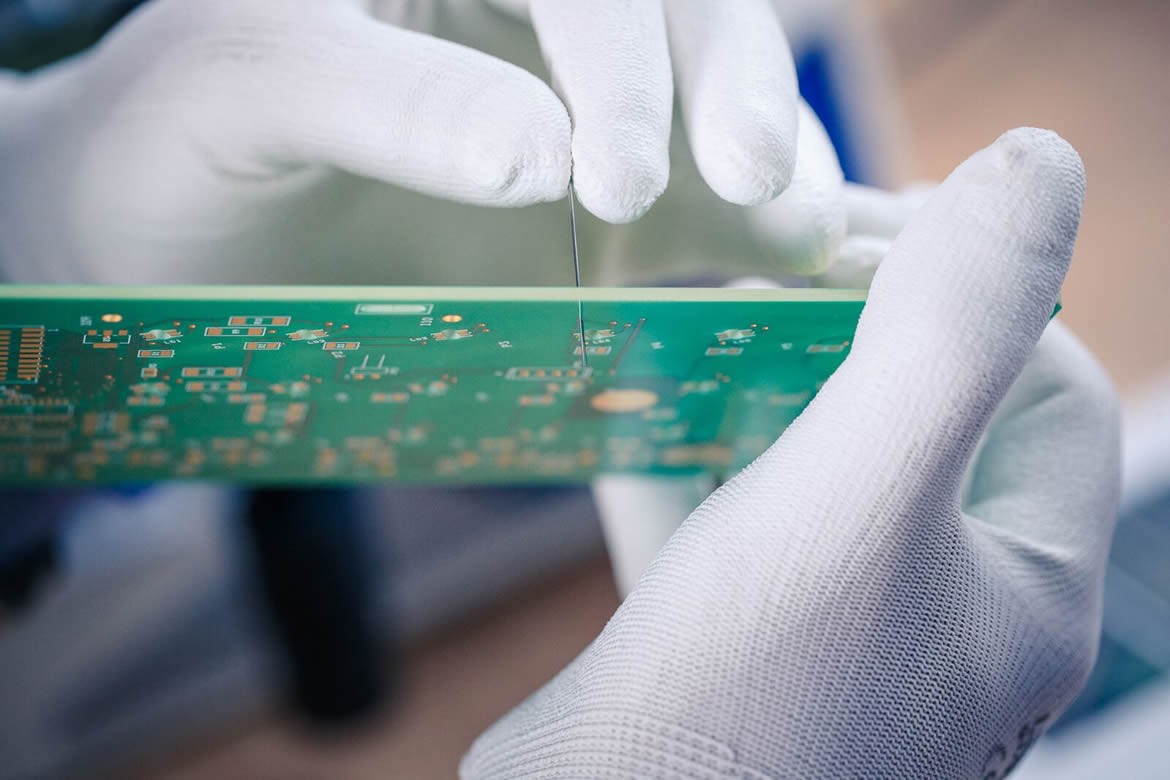

Downstream of our production process, countless technologies are advancing on a daily basis, and in view of the phenomenal pace of progress, CSM is organised in such a way as to meet the most extreme requirements of designers and OEMs that design, manufacture and assemble PCBs.

Progress is continually heading towards greater miniaturisation and integration of components, so we are now equipped with a press for multi-layer PCBs that enables us to join different types of materials, and CNC milling machines for machining non-standard shapes.

We have a particular interest in manufacturing experimental PCBs for innovative prototypes, because these samples generate innovation.

Succeeding in producing the latest evolution of a PCB is a badge of honour for us: offering the experience we have gained from experiments conducted on the materials of many suppliers, combined with the tests we carry out in partnership with customers and designers, helps us improve our offering and compete, together with our customers, in a market that is increasingly influenced by standardisation and economies of scale.

What our PCBs become:

Experimental PCBs for universities and research centres.

PCBs WITH SUBSTRATES FOR HIGH FREQUENCIES:

designed for electrical medical applications for generating radiation and/or frequencies and/or filters for photonic/laser applications; broadcasting and telecommunications: radio-frequency identification (RFID) waves, including for NFC and IOT applications, antennas, repeaters, radars, transponders and amplifiers.

ELECTRONIC DATA CARDS:

control and monitoring: human-machine interfaces, e.g. for railway, naval and smart-city applications, industrial plants, industrial and automotive engines, domestic appliances, electricity distribution networks, etc. with CAN-Bus functions for processors, controllers, integrated sensors, ARM boards such as voice synthesis, TV cameras, still cameras, thermal imaging cameras, photocells and detectors of all types.

ALUMINIUM PCBs:

aluminium PCBs are especially suitable for high-performance LED lighting applications.

INTEGRATED CONNECTOR TYPE FLEX PCBs

dataloggers, encoders, meters, sensors, membrane keypads and flexible CAN-bus.

POWER SUPPLY PCBs;

uninterruptible power supplies, power supply units and transformers, welding machines, etc.

for frequency and power control, e.g. inverters and brushless (stepper) motors.

Manufacturing such a vast range of metallized PCBs to the highest quality standards is the result of 35 years' experience and a constant commitment to conducting comprehensive controls, regardless of cost. We dedicate all this time to total control of both the product and the production process, because to be a serious PCB manufacturer, you cannot make it up as you go along, you have to achieve it by making at least one product that is different from your usual output every day.

The consistently high quality standards of CSM's output is particularly appreciated by organisations that need PCBs for applications that have to minimise the risk of error.

Against this backdrop, CSM products set the PCB industry benchmark in terms of ratio of price to features.